Results and conclusion

A drop in the middle, a cross, spread it with finger, or use an old credit card to smooth it perfectly? Even simple things like applying a thermal paste under your cooler can be a bit tricky sometimes. Commonly used methods are seemingly different, and if you also consider batching, there comes a question of how to it to achieve the best results.

Results and conclusion

It seems that the most effective technique is to create a smooth layer on the whole area of IHS. The lowest temperature was achieved with 0.1 ml of paste. However, we consider this a waste of material because differences between 0.1 ml, 0.0333 ml, and 0.0666 ml were negligible.

With the finger and foil method, the values go a bit higher, and again they tend to rise with less paste. Even though the contact above the chip, where the heat exchange is most intensive, is just as good as with the previous method.

The problem is that most of the coolers of a better quality (our Scythe Fuma included) have a convex base. That means that if you use less paste, the layer is too thin on the sides of IHS to provide optimal contact. The heat exchange on sides is not as intense as near the chip, but it can still limit the potential of your cooler.

The previous claim can be supported by the fact that the cross method was a bit more effective than the drop method when we used 0.033 ml. The cross could cover more area than the drop. However, when we used more paste, the situation changed. The cross put too much into corners and left too little for the middle. The drop seems like a more flexible choice in this case because it spreads better when enough paste is used.

It was also very interesting to watch both extremes (purple lines in the chart): too much paste (0.15 ml) and too little paste (0.01 ml). Well, you do not need to worry about cooling performance of your cooler when you use more paste. It does not take the role of a thermal insulator, or at least it is not so significant that it would be worth mentioning. The excess paste is pushed over the edges of the heatspreader. So, too much paste is not a disaster, especially if the cooler can put enough pressure on IHS, but it is still a wasteful solution. Also, there is a chance that the excess paste can get to your socket, which can cause a serious trouble.

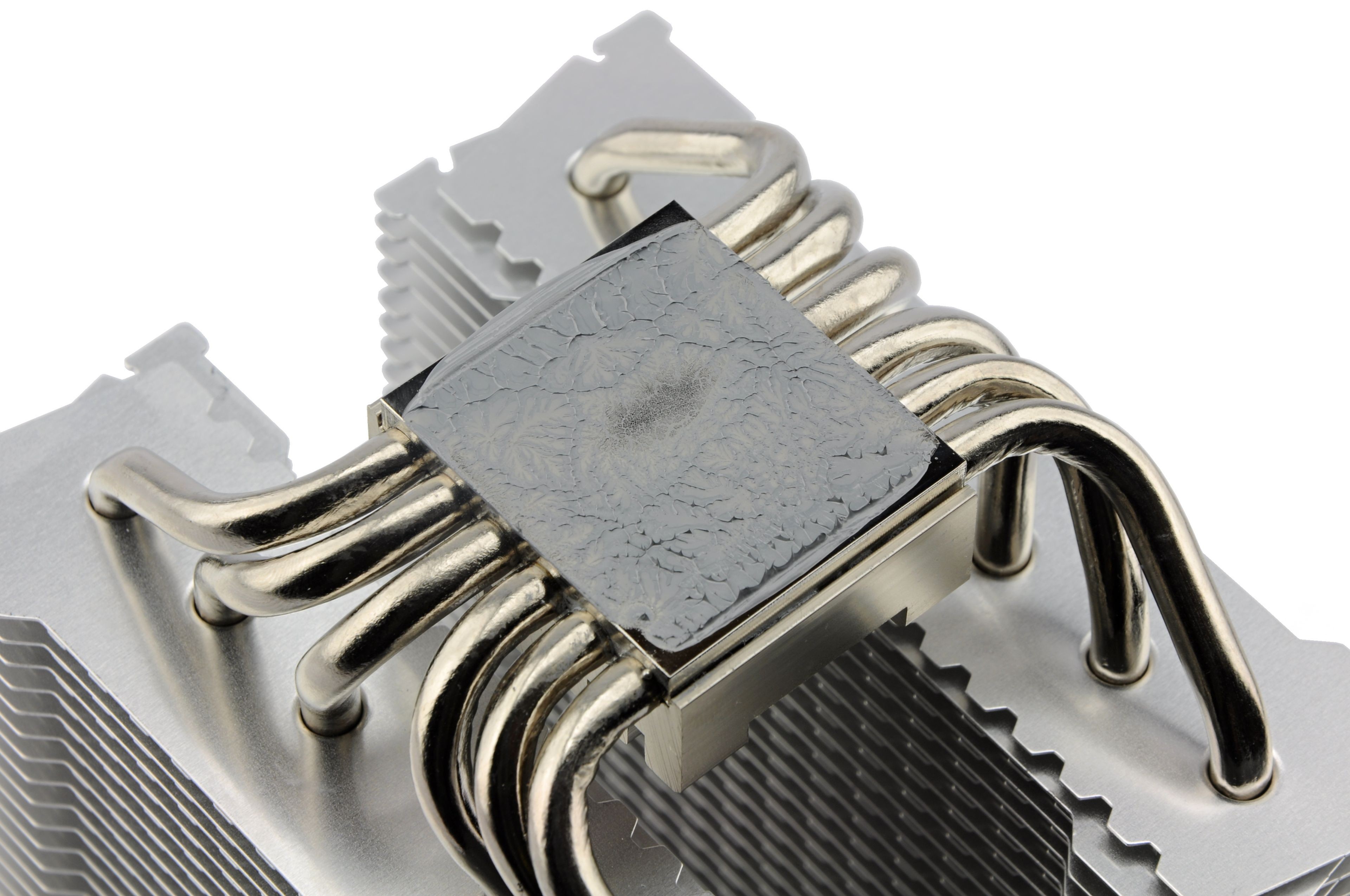

The other extreme experiment, 0.01 ml, ended worse. In fact, these were the worst results. The drop method could not cover even a half of the IHS and the effort to create a smooth layer was pointless because there were too many cracks in it. So, the rise of the temperatures was inevitable. We also tried to put a straight line across IHS, which seemed reasonable due to vertical orientation of a chip, but it fared no better than a drop.

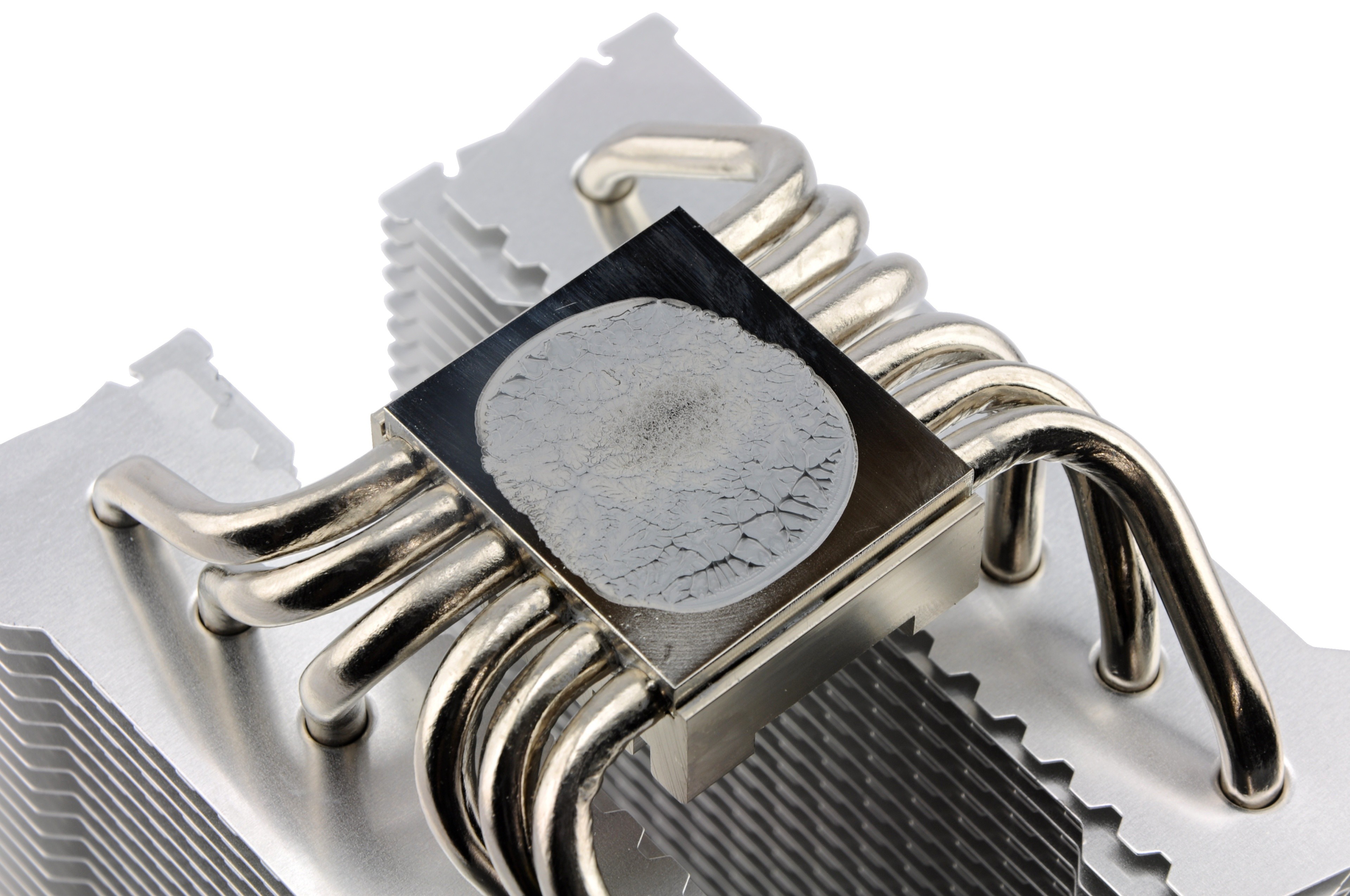

TL; DR: All in all, the best solution for coolers with a solid block base is to use the cross method with 0.03 ml of paste. Nothing can go wrong with the drop either. The final effect will be almost the same as with a perfectly smooth layer. Too much paste is not affecting cooling performance that much, but you should avoid using too little paste. The optimal drop should look like the one in the picture in the first chapter.

If you would like to give us a tip for a review, feel free to do so in the comment section.

We will be grateful for any feedback!