Details

With increasing IOPS, SSD cooling demands also increase. This applies even to powerful models (NVMe) for common customers. In most cases, controllers can take a lot, but high temperatures do not add to their performance nor lifespan and they can cause problems even in very quiet computers or in a room with higher air temperature. An additional heatsink can do wonders.

Details

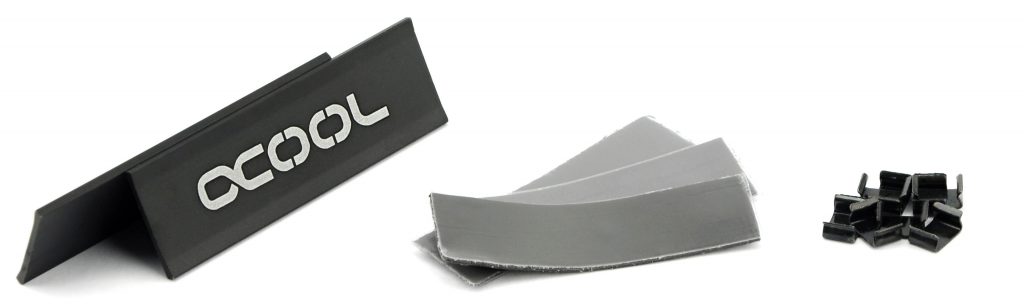

The Alphacool HDX M.2 cooler consists of two almost identical aluminum plates with a smooth surface. The only difference is the length (0.5 mm) of one of them. Rather than a technological intent, it is probably a manufacturing inaccuracy. The shorter part corresponds to the specifications (68.3 mm), the longer one is a bit above the limit.

The weight of these plates is 12 g and the thickness is 1.4 – 2 mm. At the edges of the longer sides, the material is rounded and thicker. This provides a lug for better attachment of clasps. In addition, the contact surface is slightly curved, but the radius is quite small. The sides are two hundredths of a millimeter (at most) higher than the center.

The medium for the heat dissipation are the proven Eisschicht pads. Part of the accessories are three pieces – 2× 0.5 mm + 1× 1 mm. You should use a thicker pad (according to the manual) if you own a SSD that has memory only on one side. This optimizes the pressure.

The pads are precisely adjusted, you do not have to cut anything. You can see how they fit in the image. However, do not use it as a guide for installation, they should be applied to the heatsink first. You should smooth the surface on it, otherwise it may curl.

The heatsink is designed to transfer the same amount of heat from both sides. Because of this, you can expect limited compatibility. On some boards, a solid threaded column for a shorter SSD can hinder during assembly. The heatsink is simply too thick. There can be problems with PCI Express adapters too because their slots are also close to the board. As a result, the PCB significantly bends after the screwing.

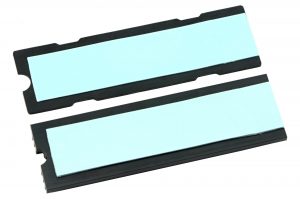

EKWB has a different opinion, and one of the few things that are similar is that their cooler also consists of two parts. The front side (the one that absorbs the heat from the controller) is rugged. The total thickness of the heatsink is 0.5 cm, the ribs (with 2 mm spacing) have a height of 3 mm, the rest is a substrate.

Compared to Alphacolol, the cooler is almost a centimetre longer. However, some SMDs are poorly covered due to the larger radiator. Those that are below the level of controller and memory and are not in contact with the pad will cumulate the heat, which may not be very positive in the long run. But this is, of course, a solvable problem.

The thermal pads are really long, enough for two fully-fledged applications. Again, a combination of 0.5 + 1mm. Unlike Alphacolol, the manufacturer recommends using the thicker one on a warmer side with the controller. This choice is supported by our tests of thermal pads. At least a wider coverage of the back side of PCB will be possible due to their extra length, but in practice it has almost negligible impact. Perhaps they could be shorter and a bit wider so they would touch the chips with the entire surface (there is a millimeter margin). But this is also a detail that probably would not improve cooling efficiency that much.

The other part of the heatsink is relatively thin (1.1 mm), which is good because there are no collisions. Basically, it is a backplate whose main function is to hold the ribbed heatsink with clasps. Here we have to praise a particularly comfortable assembly. On one side you pin down a clasp to a rib, set it to fit into the cut of the rear plate, and then pin it down again on the other side of the heatsink. Just notice the small difference in hooks before the assembly, the one for tightening the grip has a different shape. To do it the other way around is very challenging.

- Contents

- Details

- Test procedures

- Results: cooling of the controller and memory

- Heatsink temperatures

- Thermal images

- Conclusion

Ordered the EKWB cooler, it is arriving today!!!

Good choice! 🙂

Nice test! Would be nice to also compare to Aqua Computer kryoM.2 micro.

Is it possible to use the EK-Model on an Asus ROG Maximus IX Apex (https://www.asus.com/websites/global/products/Jp5t0js638s6sbJG/v1/img/kv/strix-rog-apex-pc.jpg), where the M.2’s are slotted beside the DDR4-RAM-Modules ?

Not sure but i did use 3 on my GODLIKE MB and i have a close friend that did use them on his Maximus XI EXTREME

The reason that the Alphacool did not properly cool the memory but cooled the controller a bit is because the controller gets hotter than the memory and because it is technically a ‘heat spreader’ not a ‘heat sink’ it was spreading the heat from the controller to the memory since they are all connected thermally & the ‘heat spreader’ is not thick enough & having fins/ribs etc. to properly sink the heat away.

I have a Z390 Auros Extreme, and it has the same heat sink setup as the Ultra which I also have. I was concerned with the high temps with the beefy heatsinks both bords have, so I tried the EKWB. The results are very close to the same as the stock heat sink. The only real cure is massive airflow. I’ll be waiting for a reputable MFG to come up with an active cooler, shouldn’t be hard, similar to memory cooler. Currently, I just have a small 80mm fan sitting on my GPU backplate doing the job, but it’s kind of a hokey setup for $6K rig.

I saw this a popular webstore where it was described as “Nickel”, as in the metal. Since Nickel dissipates heat better than Aluminum I was interested (my entire cooling loop is EK so why not one more emblem for them). I went to the EKWB website to the page for this specific passive cooler primarily to learn what the back plate was made of, I thought Acetal would be great with the Nickel top. Well, on their website they first mention that they have this in both Nickel and Black. It wasn’t until the very bottom, in fine print, that it informs you that the entire heat sink is made out of Aluminum, nickel I guess is a color here. Straps are Stainless Steel. Not the best configuration for an Aluminum block IMO, so I’m passing.

Usually, when a product specifies “Nickel”, it isn’t made of actual nickel, but is merely nickel plated. It’s the same for gold and silver. You won’t find a product that states “Gold” to be actually made of gold. It’s gold plated, but not pure gold. That’s not economically viable.